User Tools

.

.

Introduction to a Backyard Metal Foundry…

1. This article is for safe and mature people, because it's insanely dangerous. Your body is in danger, your eyes especially.

2. These are student notes, not professional advice. Do your own lengthy research. Don't take any risks.

3. Enjoy my notes and please let me know if you have tips and advice!

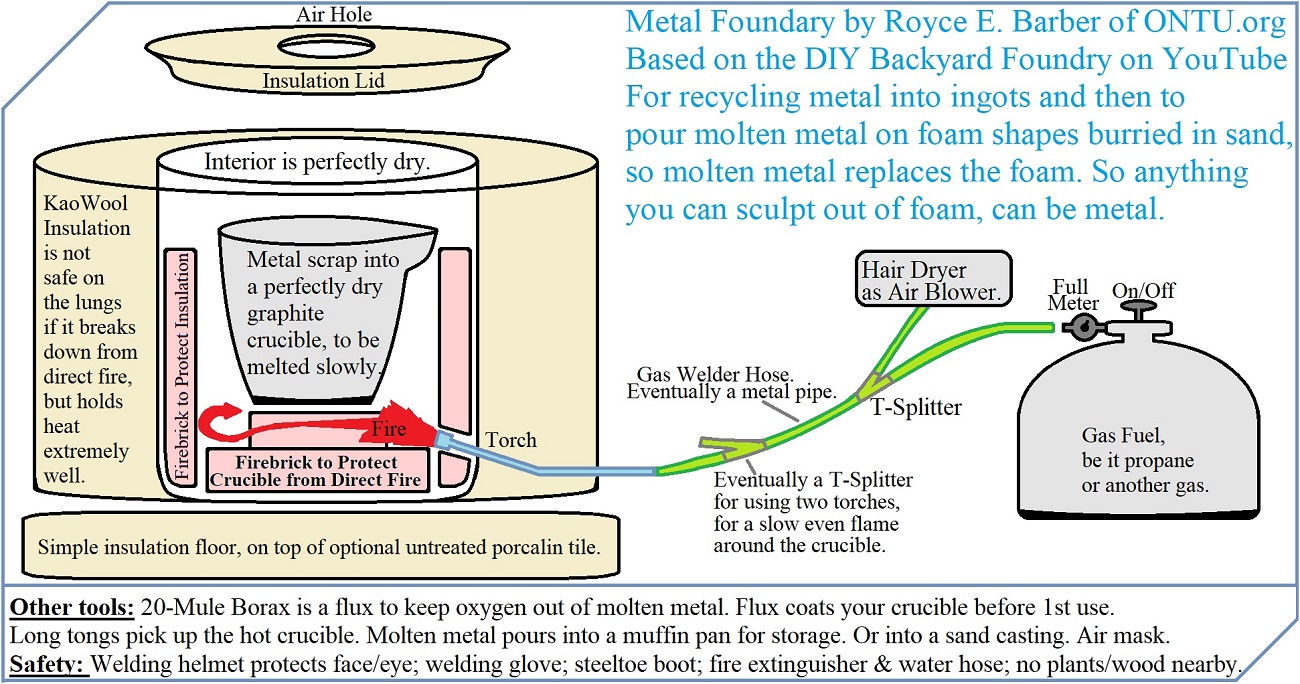

4. My first goal is to convert foam sculptures into aluminum metal.

5. This article is just a stub and shall be updated many times.

6. Molten-warm thanks to TheKingOfRandom on YouTube for his many experiments.

.

.

.

.

.

.

.

Basic Melting Temperatures for Fairly Pure Metals…

* Pewter: 250 degree Celsius. Melts very easy. Can be melted with blow torch.

* Aluminum: 660 degrees Celsius.

* Brass: 900 to 950 degrees Celsius.

* Tin: 500 degrees F.

* Copper: About 1,984 degrees F. Same with gold and silver. Copper is heavy and looks good.

* Iron:

* Steel: Very high melting point.

* Titanium:

* Lead (toxic):

.

.

.

.

.

.

.

.

Useful Tools…

Melting foundry with fuel. Scrap metal to melt into portable muffin-tin ingots. Crucible to hold molten metal. Metal cutting saw (tiny fine teeth). Thick and long gloves. Fine aquarium sand you can reuse many times. Chopped fire extinguisher as a crucible, or any pure steel crucible or official professional crucible.Tongs or a tool to pull your hot crucible out of the foundry.

.

.

.

.

.

.

.

.

Random Tips…

* A used “steel fire extinguisher” is a fairly good crucible. It's steel if attracts a magnet, otherwise it's useless aluminum.

* Dropping molten metal on concrete is a danger because concrete has moisture bubbles which will explode. Water expands fast when hot, and explodes into steam.

* Melting scrap metal will often generate “slag” which is impurities in low-grade metal.

* Accidentally kneeling on molten metal, will instantly burn a hole in any fabric and your body.

* After dumping molten metal into a muffin ingot pan, tap the crucible on stone to clean it out.

* You can quickly convert Styrofoam sculptures into metal. The finer the sand, the higher the detail. Play Sand isn't very find, but some aquarium sand is excellent.

* Save good scrap metal and soda cans.

* Silica sand will melt, don't use it for casting.

* FIRES. Fire extinguishers are VITAL. I often use a lightweight arasol can because it's light weight for instant grabbing. I use “A B C” rated, not just “B C” rated, for multiple kinds of fires. The downside to an arasol extinguisher is that fires re-ignite if they aren't thickly coated in fire retardant. You have to 100% block air from the fire. FirstAlert Tundra arasol spray is excelent for small fires, because its super easy but sadly has a thin small coverage. A fire blanket is excelent but small and expensive, has to be left there a good five minutes or the fire can re-ignite. 8ft x 8ft Fire blankets or larger are perfect if you can find one. The “Kidde ABC Multipurpose Fireextinguisher” is fairly good at $25 dollars USD, but some Badger and Sentry products last longer and can be refilled. A everyday garden hose is super useful if it's already turned on, because a extra-hot fire spreads instantly within seconds. I keep a 3 gallon metal bucket full of water, covered with a shower cap to keep out leaves, so at any time I can splash a fire. A fire can be knocked around by a high water force, spreading bits of flaming debris.

* Galvanised steel chain and some other metals put off a lethal fume, so first burn off the thin plating at a great distance where you can't smell it at all. It's preferred to never melt galvanized steel. Zinc when heated red hot, is exposed to oxides and becomes gaseous zinc oxide which can kill a human.

* Real hardwood charcoal get far hotter than briquettes.

* Soda cans aren't very pure, they produce a lot of “dross” or “slag” which means useless scum and mineral waste.

* Aluminum draws in a lot of gas, making your product a bit foam-like on the inside, so you can use flux and degassing additives to have a nice solid aluminum muffin. Cool the final cast slowly, to retain max strength.

* YouTube or Google about green sand casting using Styrofoam.

* The advantage to a “ground furnace” is the opening can be open or closed to keep the heat in. Where as a bucket furnace has a large opening letting a lot of the heat out even with the lid on.

* When melting aluminum, one spoonful of “Mortan lite salt” and “Arm & Hammer Super Washing Soda” aka Sodium Carbonate, wrapped in aluminum foil and into the crucible, will remove Hydrogen and thus eliminate your ugly pitting problem. This is not Baking Soda. Borax is another great flux chemical, useful for getting rid of impurities.

* When polishing sharp metal, it can fall and slice your leg open. Wear boots and long pants.

* Convert a Metal Foundry to GasBlaster Propane, by TheKingOfRandom on YouTube. Uses 8ft rubber hose, ball valve, couplings with Teflon tape, propane nozzle, wire feed welding contact tip, 4 socket cap screws, 6 inch steel pipe, reducer couplings, adjustable steel sheet as a regulator, washers, pressure gauge, regulator valve, flair fitting, presto-lite valve, and a few extra parts. The GasBlaster goes from 1psi to 50psi of propane. You can split your hose so there will be two GasBlastere torches, for a super fast heat. Video tutorial here: https://www.youtube.com/watch?v=eO8NwseRxSA

* * If heating your foundry quickly, the crucible could track from temperature differences, causing tension and warping in the metals.

* Dirt is an insulator, if you choose to bury your furnace in the ground, but it may take a long time to heat if the ground is frozen.

* Safety gear is vital at all times because materials weaken and break over time, causing spills and explosions. Wear long pants, long sleeves, steel toe boots, welding gloves, high-spectrum sunglasses, a thick leather hat, and be prepared for flying metal shrapnel and lethal spills. Multi-thousand-degree metal will pierce the body quickly. Stay upwind when around any smoke or fumes, as some smoke has toxins difficult to detect. An up-to-date certified fire extinguisher and garden hose shall be within reach at all times. Hair shall be tied back. Wear a face shield. Don't melt metal around trees, weeds, buildings, or anything flammable.

* Metals can be cut with a table saw and metal blade.

* Many metals will oxidize if you didn't pour in the right additives. Such as Borax being the most popular by far, and coal, salt, and other flux chemicals. I need to study the common flux chemicals.

* You may pour molten metal onto a wooden mold.

* Your propane burner won't likely work outside of the foundry, because it won't have a flame vortex (spinning flame) and will blow itself out.

* If metal has moisture in it, it will pop to evaporate, and cause sparks to shoot within a five foot area, so keep the foundry away from your house or anything that can possibly burn. If your crucible cracks and molten metal pours out onto concrete, there will also be a storm of popping fire as moisture in your concrete explodes. Crucibles only last so long, as they are heated and cooled a lot, so all of them eventually crack. Even steel factories have the rare disaster of 3,000 degree F metal spilling out into a room.

* Wear leather welding apron, a welding face mask, and leather gloves and boots.

* “Greensand” is a type of clay which looks like natural sand. When moist it holds its shape well, unless extreme heat flashes the moisture out of it. Talc baby powder prevents greensand from sticking to anything, so use a paintbrush to dust on the talc powder.

* You need a wide air gap around the crucible, for the fire vortex.

* Excess smoke can be controlled by adjusting your blower speed.

* Aluminum is easy to melt but difficult to weld, and very easy to cut and scratch, and won't rust. Steel melts much hotter, is harder to cut, but is very easy to weld, and will often rust.

.

* TheKingOfRandom replaces styrofoam carvings with aluminum, via a bucket and sand. Use quarter-inch sheets of smooth foam, and printouts of sliced-up 3d objects to use as a template. Even a Windows Paint drawing, with a sub-drawing inside of it, to show two patterns at once. Cut out the patterns, then place on foam. Making 3D layered foam objects. Foam layers adhered with spray or hot glue, or any thin layer of glue. Bury the foam object in green play sand, in a 5gal bucket, with a stick of foam comming up, then place a little cylendar of cardboard or a soup can (can opener on both sides) on top of sand to be a funnel. Pour in molten aluminum to instantly replace the foam, noting the aluminum shrinks slightly as it cools. Video: https://www.youtube.com/watch?v=tH-PaNugz9w

.

* Aluminum and other metals… Aluminum is a soft and light weight aluminum, easy to maintain, with a very thin layer of oxidation on the outside. Anodised Aluminum is a durible coating on cheap aluminum, and burns off quickly. Anodized aluminium melts fine, has a great low price, but the quality usually isn't quite as nice. Casting grade aluminum has 6-8% silicon content. Add high silicon metal, such as pistons to the melt, if you plan to do a lot of machining on the aluminum, because extremely-high alumunim content can jam up a cutting machine. Most metals are not magnetic, including aluminum, copper, silver, gold, magnesium, platinum, and more. Magnets attract iron, nickel, cobalt, steel, and more. Non-Ferrous Metals such as Aluminum or Copper, do not contain Iron, are not magnetic, are usually more resistant to corrosion than ferrous metals, and have a lower tinsile strength than Ferrous metals. Ferrous metals include mild steel, carbon steel, stainless steel, cast iron, wroght iron, and have a higher tinsile strength.

.

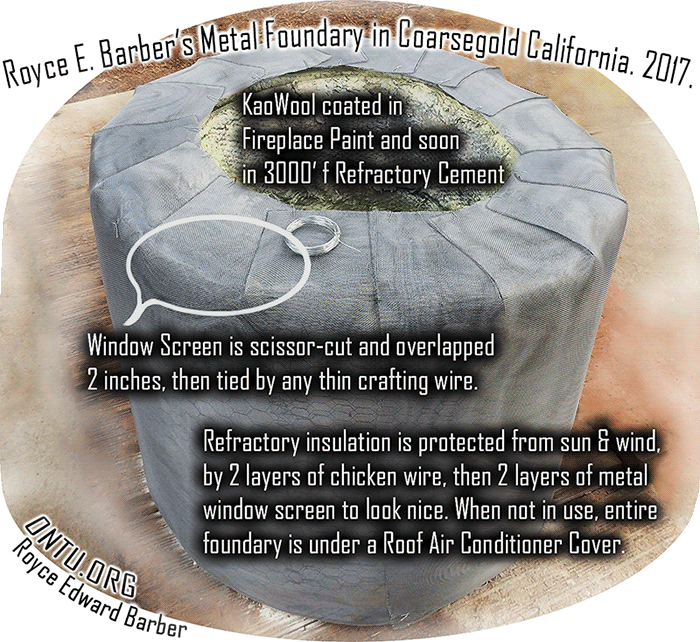

* KeoWool Insulation Details… Kaowool is made from ceramic fiber, with no asbestos involved. KaoWool's ceramic fibers are silica sand, and once cooked will break apart into short fibers which can get embede in human lungs, and thus KaoWool is often sprayed with a fireplace liner or coated in refractory cement. Wear a paint fume grade 3M mask when cutting KaoWool. KaoWool lasts far longer than fiberglass and insulates much better without melting easily like fiberglass.

.

* Your Crucible will almost certainly be made of Silica Graphite. It'll smash if dropped. It'll crack if tempature shocked. Light taps on grass are okay, but not hitting it. Don't get it wet. Common weight (how difficult it is to lift) are 1kg,2kg,4kg,6kg,8kg,10kg,12kg,16kg. 16kg is about 564 ounces. 8kg is about 282 ounce. Keep in mind, kg means the product weight and not the size. Gallon represents size such as liquid, while kg represents weight. A baseball of foam or metal has a much different weight. I personally like “#10, 12Kg ProCast Graphite Crucible” because the inside space is 6 inch diameter and 8 inch tall. Often a listing will say the inside measurement. The 5kg crucible will often only fit a soda can.

.

* At a industrial steel mill, water expands at 20,000 times per second, so a cup of water is like a grenade.

.

* Why not use an Electric Pottery Kiln? You can, it's great! They cost much more than a DIY propane foundry. You'll need to replace a few parts every so often. Your home or school Electric Kiln will run on a oven or dryer electrical outlet, which is technicalkly called 240 volt single-phase. Some homes have electrical issues and would prefer to use propane devices, if the circuit breaker pops often. A kiln on a long extension cord will 1.) Take more power, and 2.) Melt the extension cord unless it's very high grade. There are very small tabletop 110-Volt electric kilns, but the max tempature is about 2000 degrees F and the crucible is fairly small, and a part to replace fairly often is the Thermocoupler.

.

* Firebrick is often rated as K-20 through k-26, with k-20 being lower-cost and heats fast and can't handle 3000 F tempature, while k-26 cost more and can handle the highest firebrick tempatures and takes much longer to heat so you waste more fuel and lasts the longest during high-tempature. The lower the K, the faster it heats but the faster it'll crumble at high tempatures. When in question, K-23 is a middle-road area for fairly high tempature protection while still heating fairly fast. But it's the fast heat-up and cool-down that cracks and ruins firebrick, so if you only need 2000 F tempature, then in theory K-20 lasts the same as k-26 and saves you in fuel cost. k-26 lasts far longer at highest-tempature but the same longevity at low tempatures. K-20 breaks and cracks if you have multiple burners and forget it's running. Non-coated porcalin tiles can be used as a cheap floor and will crack a little but are great for protecting your expensive firebrick floor. It's expected and ok for non-coated porcalin tiles to crack, as they aren't rated for this ussage and are nicely inexpensive. IFB means Insulating FireBrick. I'm fairly sure the max temp firebricks can be is k-26 with a high concentrate of alumina and heat rated to 3000 degrees F, but these bricks are highly expensive. Every time you use your foundary, the bricks and insulation and crucible and everything get worn out a tiny bit, mostly the crucible. The entire foundry may last two years of intense fast hot heat, or 40 years of nice low heat with long startup and cooldown time and protecting it from moisture.

.

* Gold weighs more than lead because gold is more dense and thus harder, so a gold bullet doesn't deform nearly as much as a lead bullet, and in theory molten gold would sink under molten lead, rather than mixing. Gold is so soft it quickly melts into a puddle under a butane torch.

.

* Chemicals… Muriatic acid is one of the names for hydrochloric acid, it's most stable at 38% which is what many scientists use, because any higher fumes away quickly.

.

.

.

.

.

.

Price Log for my Metal Foundry…To Be Pasted Here. Of all items and prices.

*

.

.

.

.

.

.

.

.

.

Internet Resources…

.

* DIY Trashcan Metal Foundry!: https://www.youtube.com/watch?v=y2RYYBRFu1A

* Tips for the DIY Trashcan Metal Foundry: https://www.youtube.com/watch?v=l2FuvKTyRMQ

* Convert a Metal Foundary to GasBlaster Propane, by TheKingOfRandom: https://www.youtube.com/watch?v=eO8NwseRxSA

* Instructables instructions on a cheap Mini Metal Foundry: http://www.instructables.com/id/How-To-Make-The-Mini-Metal-Foundry/

* Detailed DIY Metal Foundry instructions from FlamingFurnace Blog: http://www.flamingfurnace.com/2012/11/foundry-setup-crucible-flask-and.html

* LuckyGen1001 on YouTube, tutorial for Forced Air Propane Foundry: https://youtu.be/l697pB9X5TI

* Melting copper, which can be tricky: https://www.youtube.com/watch?v=JjZqEwiIEY0

* Melting metal with a giant magnifying glass: https://www.youtube.com/watch?v=8IdjbdLdXYo

* Mixing aluminum with brass in 2017: https://www.youtube.com/watch?v=_30lR-nbpXg

* Metal casting Play Sand in 2017: https://www.youtube.com/watch?v=xFq9wpF0L8M

* Make metal casting sandboxes in 2017: https://www.youtube.com/watch?v=RO3WnltsOx0

* Melting glass marbles with electricity: https://www.youtube.com/watch?v=1yf2uBiaOmU

* Tito4re on YouTube, melts metals into tools: https://www.youtube.com/user/21nal/videos

* MyFordBoy on YouTube shows how to cast a metal part using greensand: https://youtu.be/5GSHXC6fwq4

* MyFordBoy on YouTube shows advanced high-detail Greensand casting: https://youtu.be/M95bhPrDwA0

* MyFordBoy on YouTube shows examples of using his metal foundry: https://youtu.be/HJ9YoRMoO5Y

.

* Wikipedia for Slag (Also see Dross): https://en.wikipedia.org/wiki/Slag

* Wikipedia for Dross (also see Slag): https://en.wikipedia.org/wiki/Dross

* Wikipedia for Forge: https://en.wikipedia.org/wiki/Forge

* Wikipedia on Firebrick: https://en.wikipedia.org/wiki/Fire_brick

* Wikipedia on Refractory: https://en.wikipedia.org/wiki/Refractory#Basic_refractories

* Wikipedia for Masonry Oven: https://en.wikipedia.org/wiki/Masonry_oven

* Wikipedia for Kiln: https://en.wikipedia.org/wiki/Kiln

* Wikipedia for Metal: https://en.wikipedia.org/wiki/Metal

* Crucible Steel: https://en.wikipedia.org/wiki/Crucible_steel

* Wikipedia Directory for Smelting: https://en.wikipedia.org/wiki/Category:Smelting

* Wikipedia Directory for Steel Making: https://en.wikipedia.org/wiki/Category:Steelmaking

.

End of page.

Discussion